Shopify WMS: The Key to Fast Moving DTC Brands

If you look under the hood of any great Shopify brand you'll find a few key things that they have done quite well. For many stores, having a Shopify WMS in place is crucial. Product, brand, marketing, and operations are four pillars of every great brand. For the purpose of this eBook, we're going to focus on the exceptional things fast-moving brands do on the operations front. Things like purchasing, inventory allocation, pick pack ship, returns, and automation. For stores not handling their own fulfillment, you can bet the third-party logistics provider (3PL) is handling all these things at a steep cost. So let's take a look and see what these fast-moving DTC brands have come to rely on in their Shopify WMS and broader operations 'stack'.

Part 1: Evaluate Current Operations

Warehouse and Equipment Updates

Most warehouse operations have standard operating procedures which provide a framework for how things should work. When introducing a new system the considerations for features and functionalities will be tied to the way your warehouse is set up if you're not planning to make new racking, conveyance, mezzanine, or other changes. If you are planning to make changes to the warehouse with new equipment, it's likely you'd want to make the consideration for a warehouse management system alongside preparation and plans for warehouse expansion.

Upgrades to Consider

Single or dual height conveyance

Sortation conveyance

Packaging assembly

Automated labeling

Check-weigh system

Mezzanine space

Automated Ground Vehicles

Systems Integration or Replacement

Part of the evaluation is whether or not the current systems in place, both software and manual or excel files are going to stay in place, or whether you will plan to change all of these elements out in favor of a complete warehouse management system such as SKUSavvy. Many stores that have grown an in-house system to fulfill orders through a Shopify storefront will have a 'stack' that looks like this: Shopify inventory, Excel Sheets, Shipping software. Once you grow out of this it's possible to get further with specific apps for scanning or picklist preparation. There are other apps for purchasing and inventory management and more apps for shipping. Implementing each of these along the way is one way to do it, and lots of stores get quite far using these methods. However, when you consider the time and cost of managing so many different systems you end up finding out the advantages start to decrease as you use more apps.

Sample Shopify Fulfillment Stack

Shopify inventory, Stocky, Excel Sheets, etc.

ShipStation, Shippo, Easyship, etc.

Bundles & Subscription App

Returns

Physical Pick Lists

Consolidated Stack

Shopify

(SKUSavvy) WMS - Inventory, Bins, Pick, Pack, Ship

Taking steps to consolidate your technology stack, marketing stack, packaging materials, warehouse flow, and other touchpoints inevitably ends up saving you money and time. The challenge with these types of investments is they come with time and money investments themselves and should be planned for ahead of time. Take the time to plan out and get quotes, estimate the amount of cost saved by switching and having another system do multiple tasks. Doing the evaluation ahead of time will give you a sense of clarity.

Upcoming Growth Plans

Even though it was already mentioned, warehouse equipment upgrades and even a warehouse relocation to accommodate growth should be factored into the WMS you end up selecting. If you've been growing at 30-50% or more annually and the inventory volume needed to keep pace is going to outpace your warehouse space allocation, it's time to think about another location or a larger facility. While a good WMS should be able to accommodate the move, and may even help simplify the move, it's something that needs to be looked at from a technology capability perspective. As in, if you are currently only handling inventory, and in the future will plan to handle purchasing, replenishment flows between bins, cross-docking, and beyond, then you should time the WMS purchase with the warehouse move/upgrade. Oftentimes the full capability of a WMS isn't even utilized and companies will miss out on the full advantages because what is looked at is only one part of the total problem. Factor in the time to learn a new system, and the costs associated with training on the new system. As you grow and add new employees, keep in mind that most software solutions will charge by the user and this cost should at least be factored in.

Some Math on WMS Implementation

Average Hourly Cost of a Warehouse Worker = ~$13.5

Average Per User License Cost =

Average Number of Employees Per 10,000 Sq. Ft. =

Total Monthly Software Cost Per 10,000 Sq. Ft. Warehouse =

Part II: Successful Operations Tactics

This is where you as a merchant can become successful with a new, or existing WMS if you haven't quite found your stride. Below are a few key elements that distinguish a smooth DTC operation and one that merely exists. From our experience, a lot of it comes down to two main categories. First is the teams that already have general systems operating procedures. And second, are companies that have general warehouse operations procedures down. For a company new to using a WMS, it will seem quite bulky and awkward at first because some tasks appear to take longer than without the WMS. The efficiencies are gained with visibility into product location, purchasing automation, and smarter task optimization across the labor pool available. Below are a few concepts and techniques to get the most out of your warehouse operations utilizing a WMS.

Systems Operations Plan

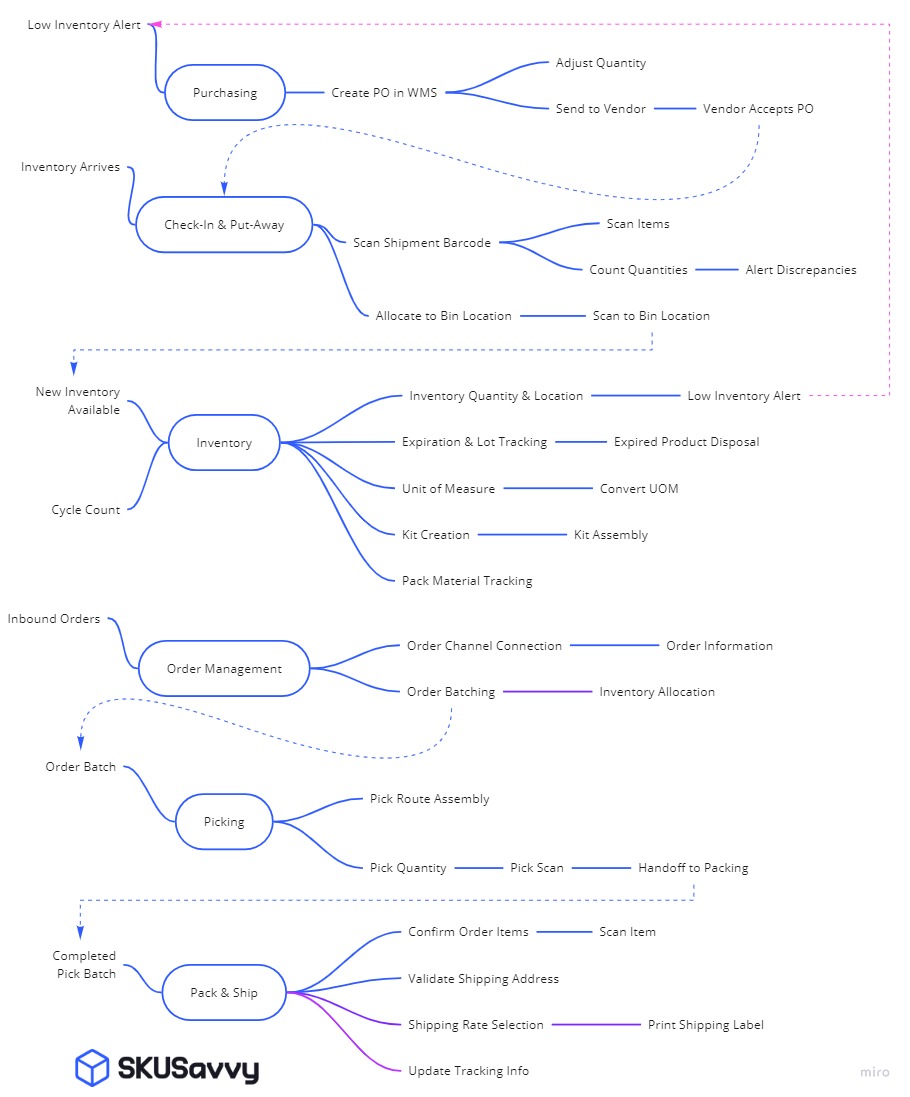

When a company begins using a WMS, it's almost always the case that part of the operation starts using the WMS and it gets adopted, and then there are mishaps that cause one or more employees to forget about tracking all data within the WMS and it goes by unnoticed. So, to clear this up, the following framework will help show what items the WMS will help to control, and by that token, where employees should be focused on entering information back into the system. The below image outlines primary tasks within the blue 'pill' shapes and the resulting actions that can be taken to accomplish that task. One thing to keep in mind is that many WMS will have varying feature sets. This is more of a baseline, although it has everything a company should need within a WMS. It is modeled after the capability of SKUSavvy.

This isn't so much about the organizational plan, rather it's to help conceptualize what tasks are involved in the warehouse so that when it comes to inputting information, it will be tracked in the right place. Some things you can do to help your team get onboard with a WMS:

Assign a WMS manager whose job it will be to enforce the usage, become a master user (for assisting others), and to add signage and/or worksheets to educate of the WMS capability

Include new tasks related to the WMS on your company all-hands meetings and daily roundups

Make sure any traditional tasks which may include paper based lists are now strictly forbidden so that employees are encouraged to input all data directly into the system

Use a mobile WMS like SKUSavvy that will be easier to adapt, and available at all times

Track productivity and errors on key metrics such as picks/hour, packs/hour, shipments/day, actions/day, on-time shipments, number of returns with wrong product etc. - consider extra training for those employees missing marks, and encourage positive usage with bonus offers, gifts, or a possible raise

ABC Analyse Your Products

One of the best things to do on a consistent basis for inventory control is to conduct an ABC analysis of your products. This type of analysis helps determine which of your products are the most valuable based on sales volume. It is influenced by the 80/20 principle or the Pareto Principle that states 80% of your success will come from 20% of your actions, and 20% of actions will cause 80% of problems. Here are a few ways an ABC analysis can help you in the warehouse:

Combine ABC data with a slotting method to organize items in the warehouse

Prioritize stock on hand for 'A' grade items

Allow higher overstock levels for 'A' grade items

Improved inventory forecasting with weighted demand

Supplier negotiation and informed buying

Reduced pick times with inventory re-allocation based on ABC analysis

Simplified supply chain & purchasing by ordering most or all 'A' grade items from a single vendor

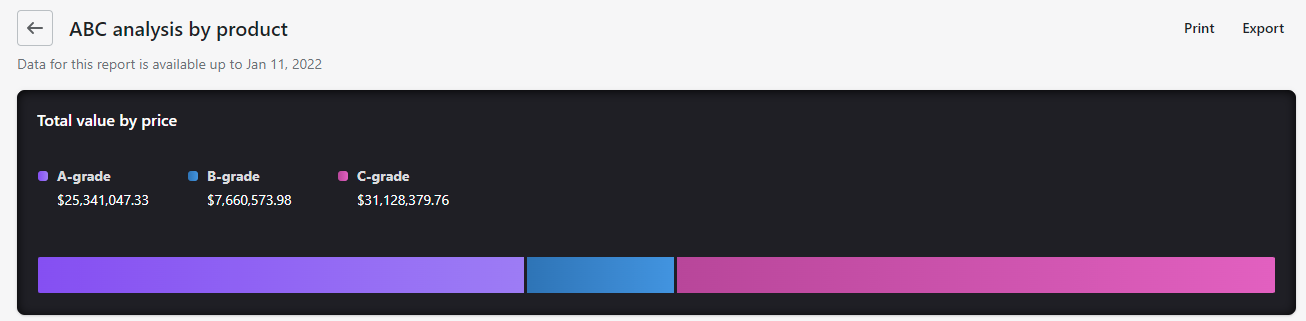

Shopify ABC Analysis Report

Go to Shopify Admin > Analytics > Reports > Inventory Reports > ABC Analysis

The run report below is for a high volume, seasonal, and high turnover product. They run multiple drops per year, and once that item is gone, it does not come back. For this reason, you see a lot of 'C' grade items.

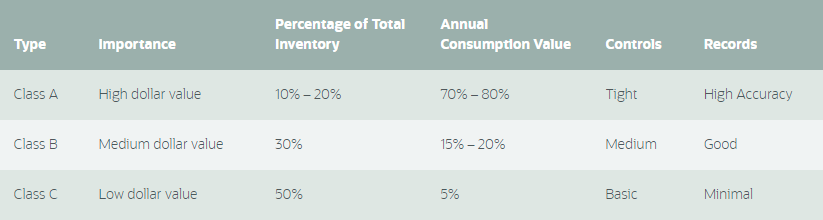

Below you can see the rough qualifications of A-B-C grade items and how they should be dealt with

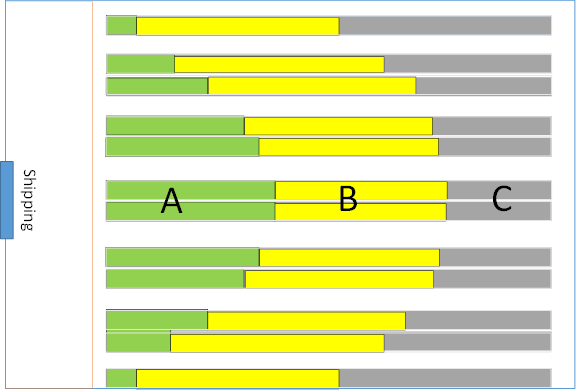

Slotting Inventory According to ABC Analysis

Using inventory slotting techniques can help your warehouse become much more efficient. Slotting is a method of allocation for items that put your higher grade items closest to the packing & fulfillment stations (horizontal slotting). It can also be used in a vertical setting whereby you place higher grade items toward arm height so it is easier and faster to pick off the shelf. In Large warehouses, this becomes extremely important so as a picker you don't spend all your time getting ladders or lift trucks to get inventory. Here are a few common slotting best practices:

#1) Slot by SKU Velocity and Grade of Product (faster moving items closest to packing stations)

#2) Slot items by zone or technology - these items may require refrigeration or lift trucks

#3) Dynamic slotting of bin locations allows replenishment items to be stored on newly empty bin locations that are the same product type

#4) Slotting based on shelf height using SKU velocity helps pickers find and pick faster

Warehouse Signage & Labeling

Probably one of the simplest ways to make the life of your employees easier is to simply use more signage and labels throughout the warehouse. This is most important for new employees who are learning the layout. Providing clear signage for aisles, levels, bin numbers etc. makes it easier for the employee to find where they are going. Use colors and numbers on large signs at the top of all your aisles for easy identification of pick aisles. This helps make the information provided through the WMS easier to read/identify and act on with visual cues. For an effective Shopify WMS to work well for you, the information provided in the WMS should very easily be seen from within the warehouse. The faster an employee can read a WMS ticket and make an association to the physical location within the warehouse the faster that employee can move through their tasks. Make it simple.

Quick Signage Wins that work well with a Shopify WMS

Use large signs hanging at visible height from many places 24"+ around the warehouse

Use more signage than less: both ends of the aisle, parallel/perpendicular views

Color and numbers will help distinguish aisles/shelves and zones very clearly

Barcodes on any place product can be stored within

Assume more direction/labels are better than less

Use a color and naming convention so it is easy to know based on the name/color where someone is in the warehouse

Bin Location Labels

On your Shopify bin locations, or any location in your warehouse holding inventory, you should have a clear label with the bin name, shelf name, aisle or level information, and a barcode. This bin location label should be easily identified by the WMS. Within SKUSavvy each bin created on your visual warehouse layout has a label generated with this information listed. By having a QR code on the bin location label itself you'll be able to allocate inventory to that bin by scanning it. This enables a scan to identify the inventory contained at this location which is super helpful for inventory control and quick on-demand information for that bin.

How to use Shopify bin locationsThe labels below are generated within SKUSavvy based on the bin barcode. It shows the shelf name, shelf level, bin name, and QR code. Newer 'pick-to-light' systems connect with the SKUSavvy Shopify WMS and can show a variety of information, updated digitally, and while picking the WMS can light up the display label showing you exactly where your next pick or put-away bin location is.

Safety Strategies in the Warehouse

Every company should implement these effective yet simple safety measures throughout the warehouse. Most warehouses do not yet have automated ground vehicles (AGVs) or pallet stacking robots, so we'll keep these measures simple for the warehouses using people labor. While safety is at the forefront of every operation, each warehouse should review the safe operating procedures each quarter to be sure it is up to date with changes that may have happened throughout the quarter. Not only is safety an imperative part of every warehouse operation, but OSHA (Occupational Safety and Health Administration - US) is always watching over the workplace. Keeping up with OSHA requirements will not only keep the safety of your employees, but it may prevent you from paying big fines if you aren't up to code. Though OSHA is a US standard, many countries have their own boards for health and safety in the workplace. It's a good idea to be congruent across warehouses, even if operating across different countries. Below are some key areas OSHA regards as safety and health hazards.

OSHA Warehouse Focus Points

Forklifts 7 other material handling equipment

Hazard communication & signage

Electrical, wiring methods

Electrical, system design

Guarding floor & wall openings and holes

Exits & exit signs

Mechanical power transmission points

Respiratory protection

Lockout/Tagout/LOTO

Portable fire extinguishers

Vibrant Coloring

One difference between Europe and the United States is the visible coloring that is required to be worn on all warehouse employees. Though this is not a requirement in the US, it should be encouraged if you have a high traffic of fork trucks in the same areas as employees. Using construction vests and bright colors improves visibility to fork truck drivers. Vibrant colors should also be used on the floor to mark specific hazard points such as near loading/unloading docks, pallet transfer stations, fork truck turnarounds, and staging areas. These areas can also be marked with lights or signs at eye level to help employees avoid those areas.

Equipment Safety Procedures

Most accidents in the warehouse come from the material handling equipment moving around the warehouse. In highly automated warehouses, this may shift toward conveyance, robotics, and palletizers though each has its safety issues. As with the vibrant coloring on people and in high trafficked areas where humans and machines intersect, each machine should have clear visible coloring as well. Machines can also utilize sensors that detect and alert people of their location via sound or vibration. Using a sense and alert technology can minimize interactions between people and machines considerably. When combined with zoning rules in a warehouse that dictates where people and machines are allowed, you have effectively minimized the hazard possibilities. Below are a few examples of zoning used to deter people from a machine space and other examples of bright-colored signage and clothing used to help machine opertors quickly identify people.

Part III: Shopify WMS Feature Shopping

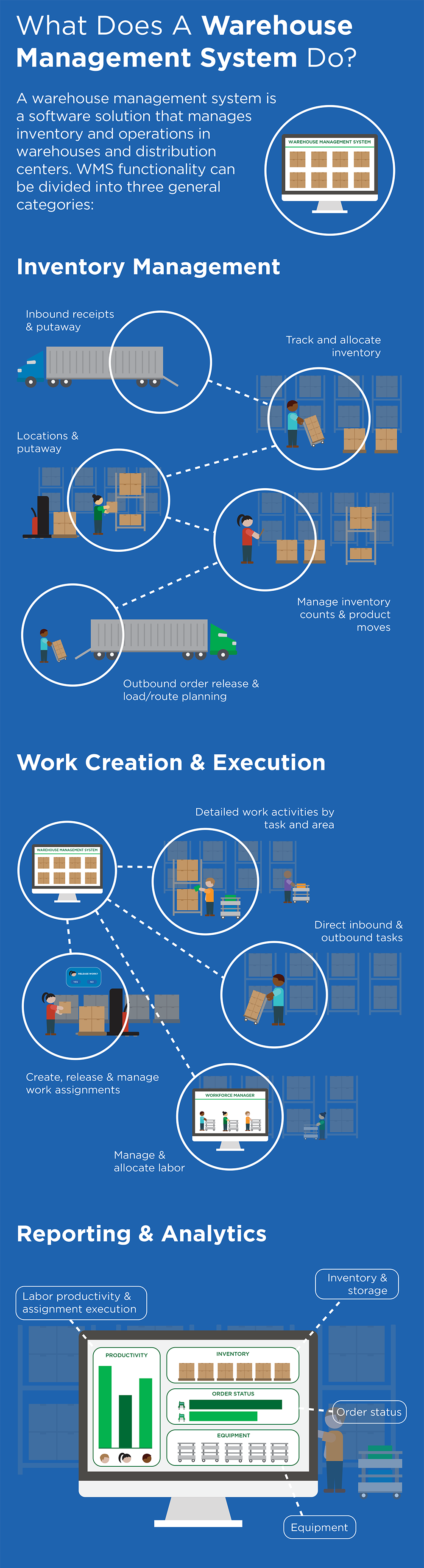

This Shopify WMS eBook is as much about making your warehouse operate smoothly as it is about helping you decide which system will get you to the next level. In that spirit, this section will attempt to lay out the critical infrastructure components you should come to expect within a WMS. Every WMS will have the basics included, but each system has its own advantages and disadvantages when it comes to the feature set included, API endpoints available, costs, and unique value proposition. We tend to think of enterprise software like ERP (enterprise resource planning), CRM (customer relationship management), and WMS as these siloed monolithic beasts when in fact modern software can be quite nimble and dare I say, light?

Tier 1, Tier 2, Tier 3 Shopify WMS

For many Shopify merchants reading this, you might be thinking about the upgrade from ShipStation or another shipping software, to a more robust inventory/WMS system. After reading online you find there are a variety of big-name companies out there offering a Tier-1 WMS, and come to find out, the system you need is far from the price tag and implementation time they are requiring. Then your search for a Shopify WMS has you land upon SKUSavvy which is designed to be nimble yet robust enough to handle 90%+ of merchants selling online. This Tier-2 system has a merchant price and nearly as many features as the big-company system. Then there are the various other systems out there that may handle a component or two but are generally considered an inventory system. So, after looking around, you find the tier-2 SKUSavvy system to be the right fit. What was it that made the solution feel right? In this section we're going to go through the unique aspects of a top-tier-2 system and why it is the right fit for your store.

Each component below is one of the primary areas a Shopify WMS should be evaluated on and the core features to expect within the component of the WMS: System, Admin, Warehouse, Employees, Purchasing, Check-In & Putaway, Inventory Management, Order Management, Picking, Packaging & Shipping, Reverse Logistics

System Specifics

At the core of every software platform is the 'stack' of libraries, frameworks, and programming languages used to make it all work. While this shouldn't concern you too much, there are a few things to at least be aware of with respect to how a system works and does what it does.

Web-based (cloud), hybrid, or on-premise infrastructure

Mobile app included or not included

Available printers

Caps on records

Feature release schedule

Setup timeframe

Directed vs. Undirected workflows

RFID vs. Barcode

Admin

Within the admin area of most Shopify WMS, you'll find a series of tools to help with employee management, tasks assignment, options for workflow setup, company properties, and certain features that can be turned on or off. Here are a few of the admin panel basics to expect:

Company properties and shipping addresses/returns

Workflow options for scaning

Picking options

Undirected and directed work flow

Carrier connections

Channel connections

Product allocation rules

Shipping rules

Warehouse admin & setup

Employees

Using a Shopify WMS helps coordinate the efforts of your employees by directing work to employees based on their roles. Keeping track of productivity within the WMS across your employee pool will help determine baselines and improve employee training.

Directed vs. undirected work assignment

Assign roles based on position

LImit data views to the assigned warehouse

Productivity metrics & report: check-in, picks, replenishment, packaging, shipments

Audit logs to track every employee

Simple employee management add/edit/delete users and roles

Warehouse

Within the warehouse, the Shopify WMS should enable you to organize each location within the warehouse including bin locations, zones, in-process, kits, or subscriptions. Beyond this, your WMS should help you work across multiple warehouses efficiently.

Add & manage multiple warehouses

Manage employees across warehouses

Cross-dock requests and workflow between warehouses

Aisles, bin locations, zones all tracked for each warehouse

Material handling equipment (tier 1 feature)

Dock doors, shipping & receiving management

Purchasing

Kicking off the cycle for inventory management within a warehouse is purchasing. Using data from the WMS POs can be generated based on order volume and lead time. Open POs become available for inbound processing and help employees track discrepancies.

Use order volume, seasonality, and lead times to predict optimal purchasing & inventory levels

Automate PO generation and reduce order friction

Send PO to suppliers and enable suppliers to confirm quantity and pricing

Manage pricing across vendors and compare total costs

Purchase independently or company-wide

Check-In & Put-Away

Once a PO has been placed and confirmed by the supplier your Shopify WMS should enable swift and accurate check-in. Being able to track shipments, files, expiration dates, and tags associated with an inbound order will keep all the relevant data in one place.

Hold inbound order information

Scan shipments, ASN, or inbound order manifests into the WMS

Scan product and confirm quantities, alert discrepancies/damages

Provide put-away bin locations with scan to location

Hold & manage quarantined, special assignment, or customer-specific orders in separate zones

Inventory Management

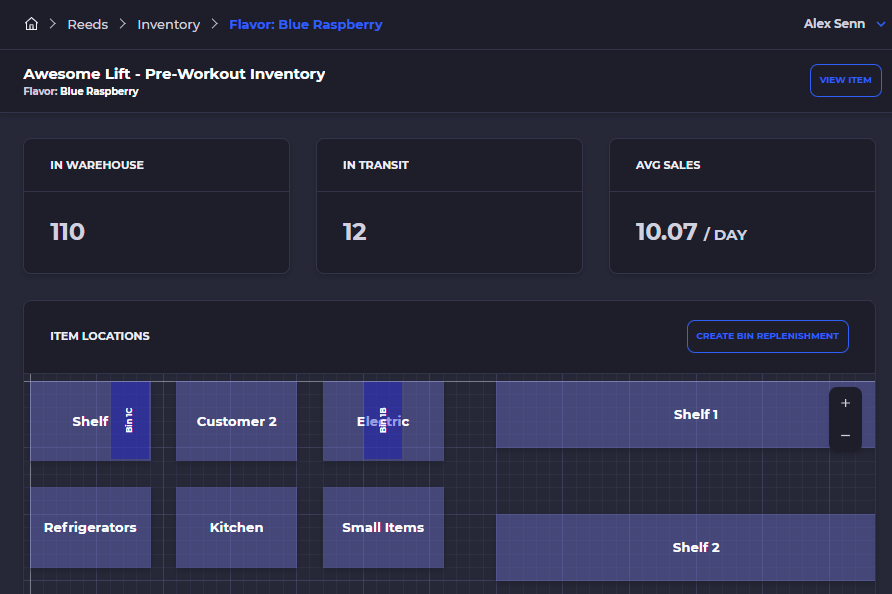

Once your orders have been checked in the Shopify WMS will keep tabs on every unit of inventory across your warehouse network. Details such as UOM, , bin locations, quantities, expiration dates, kits, and allocations are now readily available for order fulfillment.

Deal with multiple units of measurement

Track and manage kits/supplies on hand

Visual bin locations and quantities for every product

Bin to bin replenishment automation

Update and track damaged/lost items

Inventory attributes tracking

Low stock alerts and purchasing workflow

Key metrics and inventory logs at a glance

Order Management

Almost everything a WMS does one way or another ends up supporting the order fulfillment process. Your Shopify WMS should enable you to connect with various orders channels, pull order information in, and allow you to fulfill the order effectively then update the order channel.

Dual sync between your order channels and WMS

Route the order to the best warehouse available

Add/update customers, orders, shipping details

Order status and tags for workflow

Scalable real-time order sync (often-overlooked key component) for 100-1m+ orders daily

Quickly find and retrieve order/customer information and order status

Key metrics for orders and status

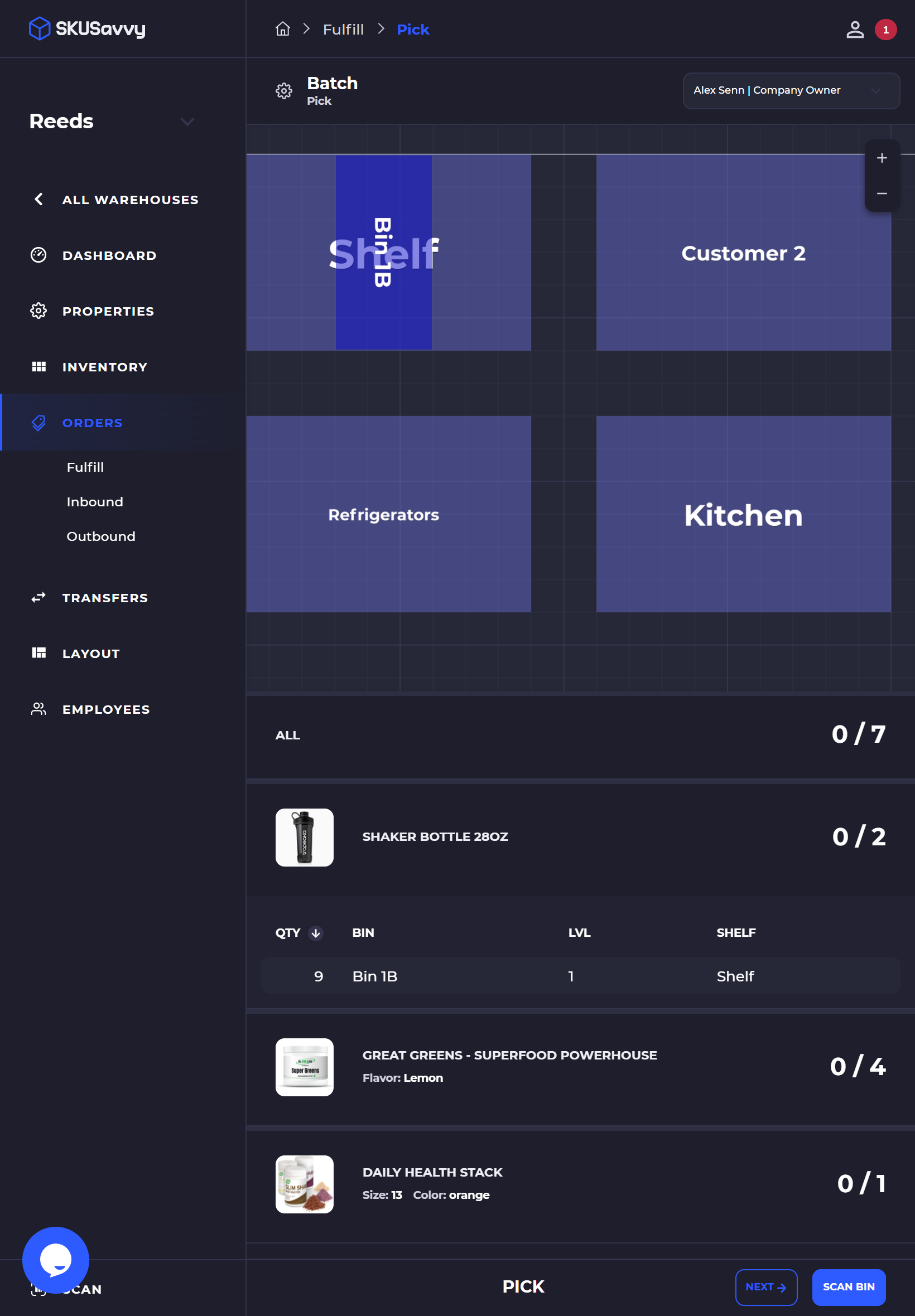

Wave Picking

With the orders flowing in, the WMS should now assist in batching orders together so they can be picked throughout your warehouse for packing and shipping. As one of the most labor-intensive parts managed by the WMS it's important to keep this as efficient as possible.

Assemble orders into smart batches putting like orders together based on product, bin locations, and zones

A Shopify WMS should hold digital pick-lists with real-time data sync for other pickers

Allocate pick batches to available employees

Create pick flows based on order types

Navigate the user through a warehouse to pick the batch

Enable scans on the bin/product for accuracy & allocate a completed batch to a zone or pack station

Deal with damaged or inacurate product location info

Packing & Shipping

With a batch of orders picked the WMS should now enable employees to package each order appropriately with the right box size and package material. As each package is completed the WMS should provide shipping details to shop and purchase a shipping label.

Hand-off a completed pick batch to packing stations

Track packing materials and make suggestions for box size on order packaging

Confirm order contents with a scan (optional)

Validate shipping address and provide a way to correct

Connect with a scale or provide system dimensional & weight details for shipping rate shopping

Multi-carrier shipping options with integrated shipping workflow

Purchase or carry over shipping service options from the order channel

Update shipment & tracking info to order channel

Part IV: Cost Consideration

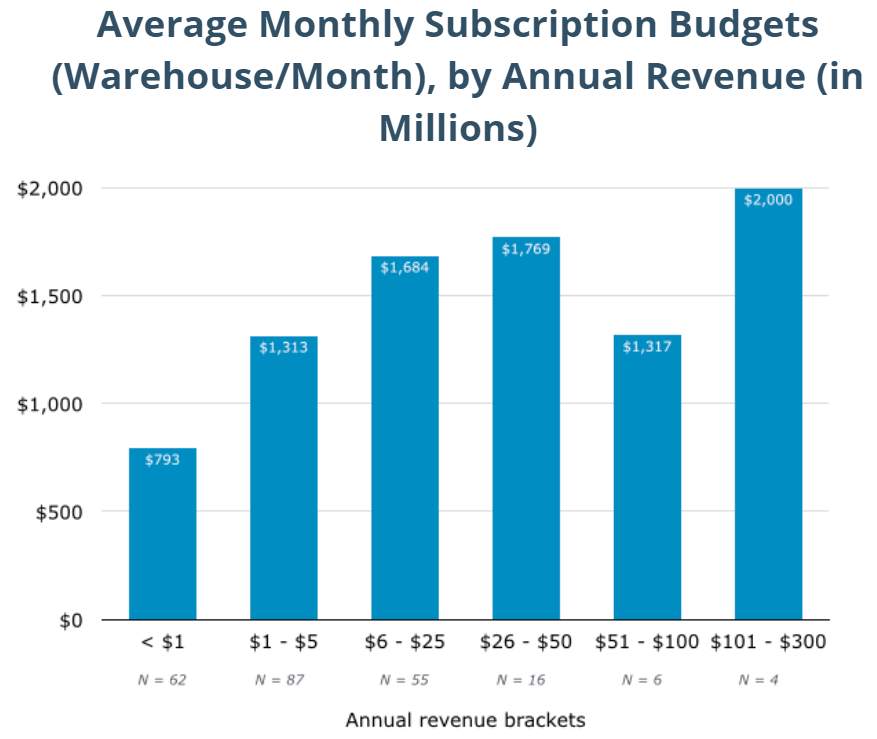

As any fast-growing Shopify seller will tell you, managing expenses in a cash flow tight business is one of the keys to success. As part of that effort, your Shopify WMS should help in a few ways to manage this cost. Ensuring your inventory isn't overstocked while maintaining effective operating stock and keeping carrying costs low is all part of the WMS's role here. Part of this consideration of course is in the setup and ongoing costs for a WMS. Keeping the system costs low is equally important in the raw cost of operating the system, as well as the human cost to operate a system, which is often overlooked when purchasing a tier 1 WMS. Balancing the benefits and features of any given WMS with the costs can be broken down into a few key areas.

Current Costs Calculation

In this cost analysis let's assume that you already have a couple of systems in place. This may only be a single system, but the way we'll go about evaluating the ongoing costs will be to pool up all systems costs associated with achieving the current outcomes involved across warehouse operations, purchasing, inventory, and shipping since these are the primary areas the Shopify WMS will aggregate into a single software offering. In this consideration, we are not going to factor in the cost of Shopify (or other channel costs) since these are not being replaced. The goal here is to simply generate a base cost for doing what you're doing on the operations side of your business, strictly on the software associated side first.

Systems & Support Cost

This will include subscriptions for software such as an existing inventory system, apps that may be doing 1-2 tasks like barcodes, bundling, order processing, and shipping software. We won't be taking shipping into consideration in this calculation. If any of the software systems you're using on the operations side have associated training or support contracts with them this should be included in this calculation. Here's a sample of what this might look like for a store shipping 5000 orders a month with 5 employees (user accounts) across 100 SKUs, 10 of those being kits (bundle):

$150/month - Kit building app

$100/month - Shipping software

$29/month - Barcode scanner app

$250/month - Simple inventory app

$200/month - Training & support

Total: $829

Efficiency Analysis

The direct costs associated with human capital to operate and fulfill those 5000 orders using your software is another consideration to make. It is not so much on the costs per hour of employee labor, though this should weigh in on your overall cost structure. Rather, we're looking at the efficiency per employee related to software cost. To give you an example let's take the cost of operations software above, $829/month, and divide that by total orders to get a per order cost of running that software. Since I'm not aware of any term for this value, we'll call it our software cost per order.

Software Cost Per Order: $829 / 5000 = 0.1658 (0.17)

Now let's say each employee can pick and pack 30 orders per hour. This is an averaged amount across a number of warehouse forums, our own experience, and industry whitepapers. Most warehouses will operate a batch picking strategy and utilize pickers and packers in a two-part fulfillment strategy. A two-person team where one picks and the other packs should be able to achieve 60 orders, so half this for one.

The average non-supervisory warehouse employee worked 40.9 hours weekly and made $17.61 per hour - Via ConveyCo.com

30 Orders Per Hour Picked & Packed

167 Hours Required for 5000 Orders

167 * $17.61/hour = $2940

$2940 / 5000 = $0.58/order in labor

Per Order Cost (Labor + Software) = $0.75

This math ends up coming out pretty cheap as a whole, however, after checking with multiple sources, it reflects around the average. This could dramatically change if your average number of items per order is considerably higher than an average of 4. This could also change dramatically based on the size of the warehouse and the travel time between picks. While not perfect, this should provide us with a good baseline for what to expect on a per order cost for software and labor.

Lowering Per Order Costs

Your cost evaluation of a new WMS should look at how much efficiency gain you can get out of your employees with simplified workflows, batch pick & pack, automated shipping labels, redundancy reduction, and more. What the calculation above does not account for is the efficiency gains from replenishment automation, purchasing automation, cross-docking, and inventory tracking. This will of course add to our per order cost. That said if you assign a coefficient for how likely this will impact the per order cost you can mess around with different efficiency gains. The software cost itself may end up going up if you are switching to a new WMS, though as a growing company you can quickly recover this and become far more efficient with your software cost per order.

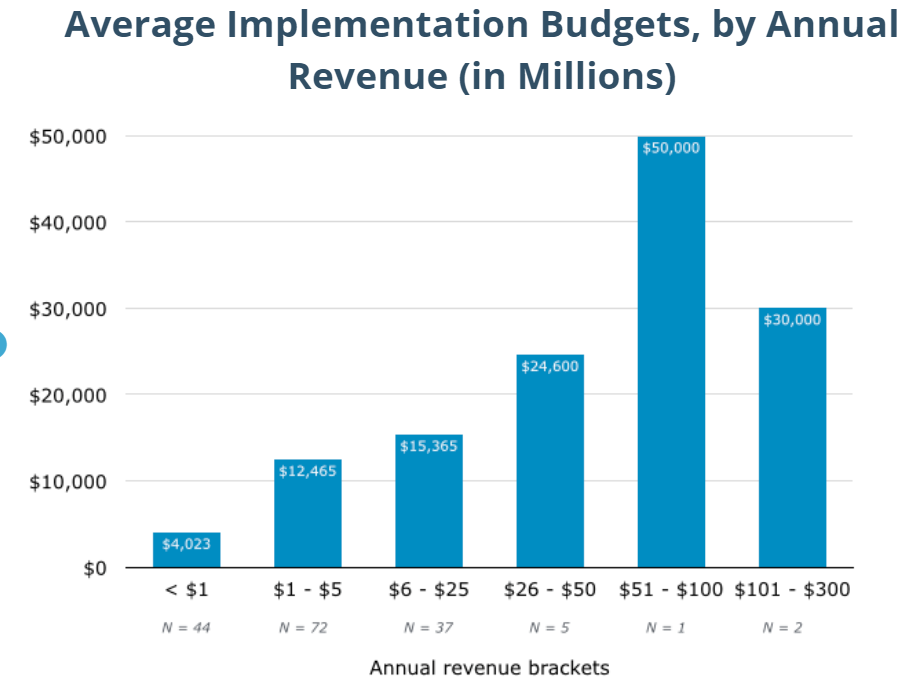

Average Costs for a WMS By Company Size

Switching Costs

When you've made a decision to implement a new WMS the first thing you should start with is the switching cost to make that WMS a reality. The switching costs evaluation should include everything related to exiting an old system, implementation, data migration, and training, as well as ongoing time to activation experienced by an employee who is slower at first with a new system.

Exit Costs

This shouldn't be a big deal, and hopefully, you won't have anything related to exit costs. However, some companies find that they are locked into a contract or there is a data export cost, or whatever else some shady companies charge to get out of their system. If you can, time your WMS migration at the end of a contract, or see if the new WMS provider will provide a buyout offer. Exit costs may also come in the form of time to end contracts and remove system data from any on-premise or hybrid infrastructure you may have in place. There may also be equipment that either you won't need anymore, or that has to go back to the prior company. All of these costs should be factored in if you're looking for a true evaluation of the switching costs.

Contract obligations

Equipment hand over fees

Employee switching costs

Warehouse layout changes

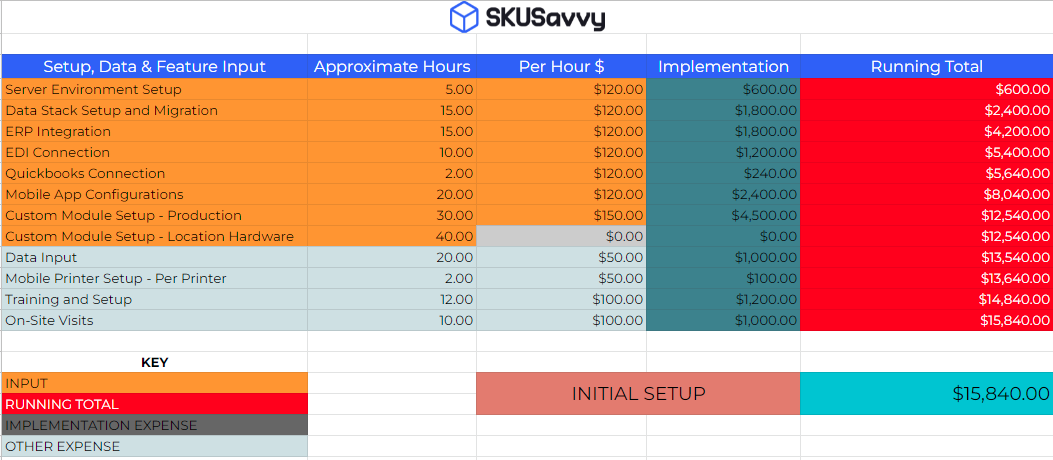

Implementation Costs

The primary cost of any new Shopify WMS is the implementation costs of the WMS itself. This includes but is not limited to data migration services, custom-built modules or features to support your requirements, data input and setup, account license setup, hardware setup, bin labels, and workflow set up within the software itself. To be clear, this cost can vary widely and will depend a lot on any customizations or heavy data migration projects that may go along with the implementation. Most WMS companies will provide an overview of these costs associated and provide a breakdown given inputs you've provided such as employee count, SKU count, turnover numbers, and orders/month.

Hardware for new system

Warehouse layout updates

Customization and integration

Employee training

Product & bin labelling

Technology Migration

When you've been running your business a certain way for years and something new arrives it can be a nightmare at first. For this reason, we're listing this as a switching cost. When people switch over to new software, oftentimes there is a consolidation of effort from multiple different software to one single software, as the case is in many of the SKUSavvy implementations. In order to do this effectively, that data contained within another software needs to come over to the new software. This cost may well be entirely labor-based. Much of the time, transitioning a big piece of software over to something new comes down to aligning the data so that it will work with the new system. It may also come in the form of aligning how the new software does something compared to the old software. With these things in mind, remember that as much data can come over, the better since new software oftentimes runs reports and makes calculations based on past data.

Data exports (some legacy systems require a 'custom script' to get data out)

Data imports

Data alignment (from old formats to new)

Workflow customization

Training & Activation

One of the most important costs associated with a new Shopify WMS is the training and activation of your employees on the new system. As we talked about switching costs associated with the learning curve on new software can be significant. So what you're really doing by paying extra for training is reducing the time to activation of that employee. I'm referring to activation time as the time it takes for one employee to become equal or more productive on a new system than on the old system. This training time will vary and depending on the complexity of the WMS you choose to implement could be lengthy. That said, it is always worth it to pay for training. You will reduce errors on the new system which could end up costing a lot, you reduce employee frustration, and you reduce the time to become productive with the new system. Something to note, some companies opt to send one or two key employees for training, who then in turn train the rest of the team. This can be an effective method, and it is always suggested that there be one 'expert' amongst your employees who can solve challenges when they arise. This person(s) may go through sustained training

On-site training (Air, lodging, time)

Remote (online) training

Training resources (situation setup, hardware setup, testing etc.)

Calculate THE ROI of a New WMS

Part V: WMS Operations Implementation

Making the move to a new Shopify WMS will go a whole lot easier if there's a plan in place so you know what to expect and how to deal with situations that come up. In the earlier part of this eBook we went through each of the tasks that should be covered by a system. Here the challenge becomes how you will actually manage the implementation from end-to-end with all the various components. Since much of the steps will be the same whether you plan to implement a new WMS or replace an existing WMS we're going to assume you'll replace an existing WMS since it is generally the more complicated of the two scenarios. For the purpose of this eBook we're also going to assume that you've already decided on which platform you'll be going with, SKUSavvy :-) The primary considerations for this transition look something like this:

Data Migration

Functionality Requirements & Testing

Integrations

Warehouse Layout

Hardware & Warehouse Systems

Bin Setup & Labels

Roles & Tasks

Training

Dry Run

Inventory Count

Switch

Optimization

Data Migration

Once you've acquired a new Shopify WMS the first step you want to take is getting some data in. This is important for a few reasons. First, it may take a while to structure the data from one system to work with another system. Second, some existing legacy software might make it quite difficult to take data out of the existing system. Finally, it's important to see what the new system will 'look' like with all your data in it. Since you might have items that require manual updates to make it work with a new system this process makes sense to get started right off the bat instead of later on. So we're all on the same page, data migration is the process of transferring files between different file formats, databases, or storage systems. Below are a few tools and tactics to make sure this data migration process goes smooth:

The security and integrity of the data being transferred are of utmost importance. You can mitigate risks associated with this by keeping data visibility strictly between individuals on a need-to-know basis. If it requires, files going from one system to another should be moved on a physical hardware storage device or over secure networks

If you plan to transfer data by making an integration, this process will involve likely an API or FTP connection. In either case, you should provide access to only those who have a critical role in making the migration happen

If one system provides a different data format than the other, you may require an interim step to rearrange the data into a format that will work. This may best be done in either excel or using another platform that your employees are familiar with, of course, making sure anyone involved has data security and integrity in mind

If in the case your data is corrupted and does not match up it is always worth the effort to get this sorted out ahead of time before importing it into a new system - many hours down the line will be saved by taking the time up front

Functionality Requirements & Testing

During the sales process for acquiring your new Shopify WMS, which hopefully you've decided on SKUSavvy, you should have clear requirements for functionality. Now that it's time to do the work of implementation, you should want to make sure those functionality components are in fact there within the software. If the structure of your implementation was laid out appropriately then it should be a straightforward process to go one-by-one through the functionality testing. This needs to happen after you've already got some data within your system and can test accordingly. Depending on the complexity of your requirements, it may require that one 'step' of testing is done before the next step can be completed. This could be something like testing batch picking, which would require inventory availability first.

This step in the operations plan should start earlier than later in the lifecycle of implementation since t's likely if you are requiring new functionality as part of your implementation, there are going to be some tweaks that need to be made. After all, we are talking about software here. In addition, it's worthwhile to continue testing throughout the lifecycle of the project. This will help understand the new software, and help catch anything that may not work as you expect it to. Beyond the functionality you expect is the integrations that need to happen to make things work with your existing setup.

Integrations

Ah yes, integrations. Certainly a big part of making it all work, and yet it's one of the most cumbersome aspects of any major software. For this reason, make sure you choose your integrations wisely and minimize the number of systems that must communicate together. It's also a reason to consider software that has functionality built directly within the software instead of relying on third-party connections. This is not always possible, and so long as the integration is tested and the bugs are worked out, can provide useful advantages for using it. The same framework for making a new integration should be used as that used in new functionality requirements for your Shopify WMS. Here are some key things to remembers about integrations:

Minimize the number of integrations where possible - it is almost always worth paying extra for native functionality that relies on added integrations (though rarely possible to get it all)

Integrations update and change all the time - so it's important to factor in the time to update and maintain those integrations

Ask your WMS providers how many integrations are 'behind the scenes making things happen without you even aware they are integrating with it

Evaluate the build or buy decision on integration, and even ask the provider how much it might be to make the capability possible (if it's not a major platform but rather a small feature set you are trying to integrate)

Warehouse Layout

How your warehouse layout looks before a WMS and the way you want it to look after may be different from each other. You may be adding capacity, moving packing stations, upgrading to taller shelves, or any number of things. This all needs to be dealt with and adapted to within the WMS, and within your own operations practices. As a part of your consideration for the upcoming warehouse layout, you should also consult with the new provider on options the WMS might enable or prevent you from considering in the new warehouse layout. This also becomes important when looking into new conveyance and sortation, check-weigh systems, and automatic labeling as all these items have major impacts on how the WMS will be implemented for your operations.

Beyond the physical layout of the warehouse is how the Shopify WMS will enable you to visualize this layout for wave picking, batch picking, zone picking, and beyond. SKUSavvy is a one-of-a-kind WMS that actually enables you to match the physical layout with a digital layout any way you have it set up. That said, other WMS will usually have a list of locations that use a naming convention (boring!) and if you are changing the layout, it all needs to be reflected in the WMS for pick simplicity.

Materials Handling, Hardware, and Systems

As your warehouse increases in size and complexity, it's very likely to require material handling equipment, sortation, conveyance, in-line scales and printers, and beyond. These elements in the warehouse make things far more efficient, and can also cause a significant investment of time and money to set up and perfect. If the plan is to invest in both a WMS and hardware systems, or if you already have hardware in place, it's certainly going to be taken into consideration with the implementation and operations plan. The two components have a heavy reliance on each other and it's important to understand this relationship for all parties involved.

Examples of how the WMS interacts with material handling systems:

WMS provides data to in-line scale for label purchasing or check-weight

WMS provides shipping carrier data for sortation belt

WMS holds location information of the product to be picked on flow track

WMS sends data to an in-line shipping label printer

WMS provides dimensional information for a box assembly machine

Bin Setup & Labels

Along the lines of warehouse layout, an important step beyond this is the actual bin setup and labeling, along with product labeling. Bin setup realistically should already be determined in the warehouse layout such as the type of bins: pallet rack space, wire rack level, shelf dividers, blue bins, etc. but what may not be set up is the labeling system for those bins. Most WMS (including SKUSavvy) will provide a generated label for each bin that can be printed out and added to the bin itself containing a name, location, barcode, and a variety of other information. This bin label may also be an electronic label that adjusts based on the product contained in the bin. Electronic labels can also light up to offer pick-to-light or put-to-light functionality if required. The most important thing about the bin labels is that they A) have a consistent look with the most relevant information B) have a way for you to scan the bin. Within SKUSavvy for instance the bin label is generated, and when you scan the bin, SKUSavvy will provide quick access to the bin contents or enable you to allocate more inventory to the bin directly.

Note: the best method we've found for bin labeling is to use either 2x4 or 1x4 labels which are stuck onto a magnetic strip (or printed directly on a magnetic strip) so they can easily be moved

Aside from the bin labels are the product labels. Most products now come with a barcode already printed on the single unit and up. However, there are times when the product is not barcoded on the single and it can make things difficult. In this scenario, a few things can be done, since most WMS will require a barcode on the product for ID and verification. First, contact your suppliers and see if they can provide a barcode on the product. Second, you might be able to print a barcode for the single and place it right next to the bin location which will serve as the barcode for all singles in that bin. This leaves room for errors, though it is a good solution in the short term. The problem then becomes if you need to scan a product on the fulfillment, which is harder to solve and might require a digital barcode to be made for the product on a computer screen. SKUSavvy will help address this issue for you with multi-barcode detection, real-time barcode printing, and error coding on an improper scan.

Use GS1 for Generating New Barcodes for your ProductsRoles & Tasks

As you either come into the world of operating with a WMS or switch to a new WMS, the roles of your employees may very well change based on a variety of factors. At the very least, you'll need to have someone with the role 'WMS Expert' who should take extra time to understand every single component of the WMS so they can help solve challenges for other team members when they are struggling, without having to call and spend money on support. It's also wise to have a few other support roles such as an internal champion who encourages usage of the new system, and someone who will help by working 'on' the WMS instead of 'in' the WMS. By working 'on' the WMS this person may be responsible for setting up automation, optimizing workflows, rearranging where the product is located so pick paths are more efficient, and generally making it easier for others to do their job 'in' the WMS.

It's also important that each of these roles assigned within the WMS have the correct permissions to do the job assigned, without giving away too much information that could lead to compromising data leaks. The tasks you decide to give your employees will of course determine who will receive what information within the system as a whole, and this is imperative to doing their job right. When the WMS operates efficiently, the vast majority of the 'work' is directed by the WMS directly, without anyone having to assign the workload. This brings up the next point, which is how those people do their job most efficiently, and that starts with training.

Training

One of the highest leverage activities you can do at the beginning with a new Shopify WMS system is to train people appropriately. It is (almost) always worthwhile to invest in training your people how to properly deal with their own job roles and the possible scenarios that might come up along the way. Training may come in a variety of ways which could include on-site training from SKUSavvy (or other companies), online training, white papers, guides, video tutorials, and in-house training from your own internal expert. When should you start with the training process? As soon as possible. During the setup of a new Shopify WMS, there is no reason your employees shouldn't start using a system right away. Your people should start exploring and using the system on their own time, as well as during training time. Since this implementation can many times take months to complete, there is no reason why by the end of this time your employees are not quite experienced in using the new system. Here is a rough outline of training activities that might take place:

Mobile vs. Desktop Usage

Warehouse layout and setup - changing bins and order of items

Inventory mastery - adjustments, removal, error prevention, mistake fixing

Directed vs. undirected workflows

Picking workflows

Fulfillment workflows

Bin replenishments

Safety stock vs. pick stock

Work-in-progress inventory

Order management and channel flow

Returns flow

Dry Run

Finally, the first opportunity to put all your hard work setting up the Shopify WMS in a dry run. Your dry run might use dummy data or a development store to push orders through but in large part, it should be as close to the full-scale implementation and operation that will happen in your live environment as possible. This dry run should test all hardware and equipment in the warehouse and should enable you to clearly see the full scale of what the system is designed to do. Here are a few things that should be tested during the dry run:

Hardware and package handling equipment

Scanning devices and mobile connection with/without internet

What happens when power is cut or the internet is out in the middle of your day

Integrations check and data integrity

Unit tests for quantities, values, and time tracking

Bin locations accuracy and random checks

Labels for bins, products, zones etc.

Fulfillment station operation & materials preparedness

Order channel sync and update

Carrier connections

Picking formats

Replenishment workflows

Warehouse layout and product workflow

Check-in workflow

You may also decide to run a full-scale live test. This should be done if the 'damage control' measures are put in place so that the operation is isolated to a few orders at a time. For instance, our clients with SKUSavvy will during implementation run a live test with one batch of orders after the product is allocated to bin locations and the sync with Shopify is in place. It is easy to run this because the damage is limited to only those orders contained within the one batch, and can easily be manually updated or changed if something goes wrong. All in all this dry run should prove that everything is moving in the right direction. If you are using hardware systems such as sortation belts, label printers, in-line scales, etc. you will want to be absolutely sure that the right information is going to the right system so the Shopify WMS is confirmed to be communicating what and where it needs to. This might include trying different carriers and shipping preferences too alongside various pick methods, label formats, customer types, and beyond.

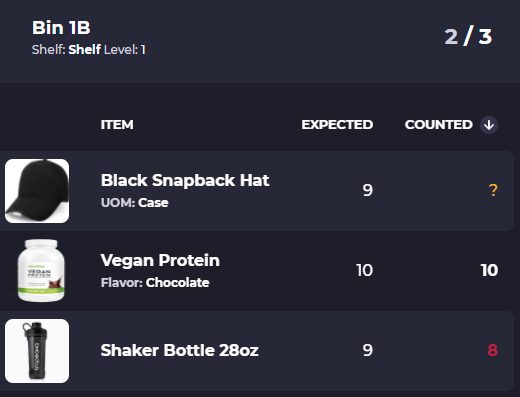

Inventory Count

In the days or night leading up to your go-live date after everything has been set up and tested it's time for the inventory count. This count might not be necessary if you've already got live data and can pipe over the data from an existing system. That said, many companies choose to utilize this time of switching as a good time to start off fresh and accurate with a count. Of course, with a modern system like SKUSavvy, you'll be able to perform a cycle count and simply go through each bin one-by-one and count/update the inventory automatically, as seen in the image below. Alternatively, you can have each item counted and updated directly within the new system manually. This manual approach is the same as cycle counting, except the cycle is one day. Lots of companies will pay their employee's overtime to stay late or overnight so that they are ready to start fresh the next day. Any way you do it will work so long as you are starting off with accurate inventory.

Switch it on

You've gone through all the steps to get your new hardware set up, creating new user accounts, migrated data, going through a dry run, and now it's time to switch the new Shopify WMS on. If everything up to this point has been executed successfully then it should be relatively straightforward by simply doing the actions of everyday operation now in the new system and not in the old systems. That can be easier said than done when dealing with complex software, so here are a few things to keep in mind when switching over:

Are your orders routing directly to the new Shopify WMS only?

Are employees accessing your new system and making all actions within the new system?

Is data synced back to order channels or ERP accurately updating?

Is directed workflow popping up on employees' accounts?

Are actions executed in the new account to create work instead of the old system?

Are new hardware systems reading and acting according to new system data?

If everything is coming over smoothly then congrats, you've got a new system up and running! Of course, this should be monitored for a few days, and old systems should still be checked for at least a week to make sure there isn't duplicated actions happening across both old and new systems, and that customers orders are updated from one single source of truth and not two. Once it's confirmed the old systems are no longer needed, make sure to cancel those subscriptions so you aren't paying extra.

Optimization

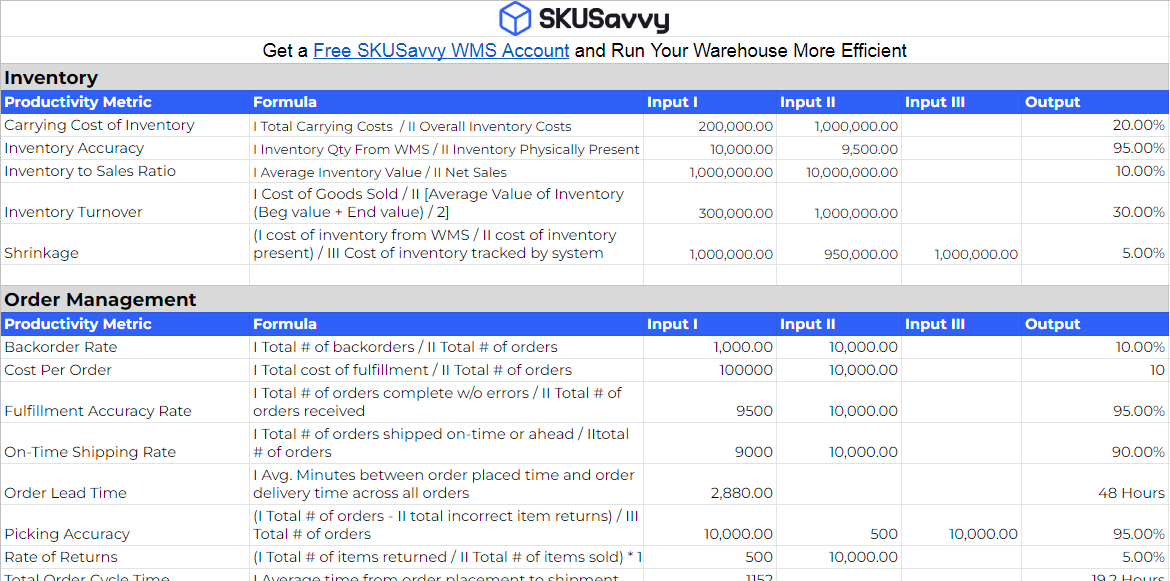

When it comes to warehouse optimization the WMS is your first line of defense. A WMS will be able to tell you exactly how productive your warehouse is and how productive each employee within a given warehouse is. The hardware you've chosen to implement in a warehouse can also be a good starting place showing at each station or each checkpoint how many packages/items or weight is being sent across sortation and conveyance belts. There are many studies on warehouse optimization so here we'll keep it fairly brief and instead provide a few resources for how such optimization tactics can be put in place. Keep in mind that with new systems you might end up less productive immediately after implementation than you were before until the employees become fully activated. Here are a few good benchmark metrics you should track and improve:

Cost per order: labor, packing supplies, storage costs, return costs

Average pick time per order

All in fulfillment time per order

Picks per employee, item actions per employee (how many items did the person move)

Cost per box shipped

Warehouse throughput

On-time shipments

Tracking and improving upon these metrics will get you a long way in your warehouse optimization journey. Of course, a critical component to this is having the systems in place to get all these numbers in the first place. Part of this comes from the WMS, and part of it comes from your regular financial statements. The WMS can get you a long way, and consistent improvement should always be the goal. There are many of warehouse optimization strategies you can implement, a few great resources can be found below:

Free Warehouse KPI Excell Template

Part VI: Successful Outcomes

The real success of the new Shopify WMS is not so much what the WMS can do for you. Instead, it becomes more about what you can do with the WMS. At the end of the day getting people on board with using a new piece of software is hard. Using the system correctly and making sure everyone is doing their part in that becomes the most challenging part of the long-term success of your operations plan. Yes, there are many other pieces that are important in this, and a well-functioning system with modern features that make it easy for you to accelerate definitely helps. Some outcomes you might experience are on the intangible side, such as overall less stress and more structure, higher accuracy, and streamlined processes. All of these go a long way to improving the warehouse. Below are a few examples you might experience with the implementation of a new WMS and why it's the key to fast-moving DTC brands.

120% Improvement in Pick Efficiency

20% Lower inventory carrying costs

50% Reduction in Orders with Errors

25% Lower cost per line item picked

33% Faster order cycle time

40% Lower cost of software associated fees

Coming to conclusion here and while the metrics above may be in-line with companies of a certain size, you should always keep things in relation to your industry, your internal company operating metrics, and the guidelines provided by your new WMS. If you are driven to improve metrics across your warehouse, it is possible to continually improve over time. With the right systems in place, correct usage of warehouse material handling equipment and warehouse layout, and a rockstar team of people ready to leverage the tools mentioned here, there can only be one way to go. From all of us at the SKUSavvy team, we're in your corner. If you're looking for a WMS and we might be able to help out in the WMS selection and implementation, please reach out.

Looking for a WMS Solution? Send us a message