How to Reduce Your Fulfillment Costs: A simple guide for eCommerce brands

6/4/2022

Imagine you found a product with all the characteristics of a top seller. It has high sales volume, healthy margins, and low competition. You know you’re onto something big — until you check your fulfillment costs.

High sorting charges, storage fees, shipping costs, and other related expenses will slice away at your margins. Now, your winning product looks much less promising; in fact, if you add in marketing costs, your star product could become a flop.

Sound familiar?

You’re not alone. High fulfillment costs remain a key challenge in growing eCommerce brands, with the average online retailer spending a whopping 70% of their order value on fulfillment charges.

Source - eFulfillment ServiceNo need to fret though — lowering fulfillment costs is still achievable.

This post will explain how securing fulfillment cost savings pay off for online retailers, then explore the components of a cost-optimized fulfillment strategy. We’ll also share some tips and tricks to help you lower fulfillment costs and protect your margins.

Table of Contents

Cutting back: How lower fulfillment costs pay off in eCommerce

The anatomy of a cost-effective fulfillment strategy

A guide to reducing eCommerce fulfillment costs

Wrapping up – The blueprint for profitable eCommerce fulfillment

Cutting back: How lower fulfillment costs pay off in eCommerce

Whether you operate one online store or three, the benefits of slashing fulfillment costs extend beyond recording higher profits and sales on your year-end statements.

Prioritizing cost reduction in your fulfillment strategy will gain you many businesses-boosting perks that can help you get and stay ahead. Let’s dig into these dividends.

1) Freedom to scale your way

No matter where you are in your eCommerce journey, cash is king. It plays a crucial role in what growth vehicles you can access and determines how quickly your business can scale.

Increased liquid cash availability from lower fulfillment costs allows you to be more selective in your scaling strategy to expand in ways that match your brand mission and goals. As a result, you’ll be more likely to attract your dream customers and scale even faster.

2) Fewer abandoned carts

High fulfillment costs place additional financial demands on your eCommerce business, straining its cash flow. Soon, you may have no option but to pass on some of the expenses to customers, which hurts your conversions.

This issue is so common, 63% of shoppers have canceled a purchase because of high shipping fees. But with low fulfillment costs, you can prevent abandoned carts due to shipping fees and preserve sales.

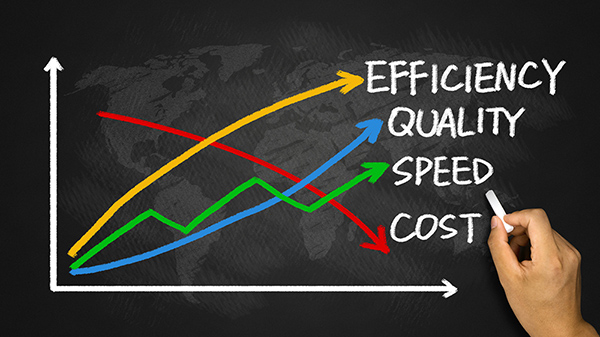

See how important shipping price is in conversionExtra: how to prevent abandoned carts3) Higher customer satisfaction rates

Reduced fulfillment costs equip your business to be the hero in the buyer’s journey by yielding cost savings you can pass to customers. Also, as you optimize your fulfillment strategy, your efficiency and accuracy are likely to increase. This means you can offer more and better shipping options like next-day shipping and locker drop-offs, further improving your customer experience.

The anatomy of a cost-effective fulfillment strategy

As many eCommerce businesses learned from expensive supply chain issues pre- and post-pandemic, saving cash while getting orders to customers quickly is a main priority.

However, it can be challenging to pinpoint the components of a fulfillment strategy optimized for cost efficiency. Luckily, we’ve got you covered. Let’s hone in on some key characteristics of a cost-optimized fulfillment strategy:

Optimal inventory levels – A tell-tale sign of cost-effective fulfillment is healthy stock levels and turnover. Stockouts, overstock, and dead stock incur additional expenses that ramp up overall fulfillment costs and thus reduce profitability.

Strategic stock placement – A fulfillment strategy designed to reduce expenses will place stock in ideal locations to reflect the store’s seasonality trends. For example, you may arrange for more stock in central warehouses during Q4 for faster distribution to surrounding towns and suburbs.

Fast, fair, and scalable fulfillment services – Outsourcing to a 3PL or prep service with reasonable, transparent pricing and the necessary infrastructure to grow with your brand sets a strong foundation for saving money on order processing.

Technology-backed supply chain management – Supporting tech solutions that monitor things like expenses, inventory distribution, and sales velocity help drive down costs.

Agile approach – Most online stores look different from how they did last year or even last month. So, a fulfillment strategy built for cost savings strives for continuous improvement to maintain long-term savings.

Some keys to reducing eCommerce fulfillment costs

Whether you need to stop cash hemorrhaging from your eCommerce order processing or want to unlock the next level in your fulfillment strategy, you can achieve your goals with the right approach. Let’s dive into some money-saving steps to take.

1) Audit your current fulfillment setup

Before you charge into lowering your fulfillment expenses, it’s important to understand what your costs consist of right now. So, make a list of all the services and products you’ve used in the last quarter and the services you anticipate you’ll need in the next six months. Some areas to include are:

Core services (e.g., restocking, pick and pack, returns processing)

Freight

Packaging

Customer order shipping charges

Ad hoc items and services

2) Cut out “nice to have” services

Unless you manage everything with an eagle eye, it’s easy to wind up paying for unnecessary services and tools in your eCommerce business. So, the next task is to remove all non-essential expenses related to your order processing.

For example, if you pay a 3PL to label your products, you could shrink your bill by asking your suppliers to include these services in the manufacturing process.

Pinpoint the “nice to have” products and services hiding in your fulfillment strategy by going through the services listed in your audit and asking yourself:

Is this service/tool essential for scaling our eCommerce business?

Will our customer experience be negatively impacted if we ax this service/tool?

Will our fulfillment quality dip significantly without this service/tool?

If you answer “no” to these three questions, removing that service or tool is a good call.

3) Negotiate costs for mission-critical solutions like your business depends on it

It’s critical you secure the best deals for the non-negotiable services you need to achieve your business goals. The trick is to use your eCommerce wins to earn the trust and support of suppliers and carriers.

So, if you have a handful of winning products in your arsenal or operate a store with high order volumes, now’s the time to shout about it to earn better rates. For example, you can leverage economies of scale to gain reasonable rates on things like:

Packaging

Dunnage

Shipping

Warehousing

As a concrete example, imagine Q4 is fast approaching and you’re confident you can commit to fulfilling 2,000 more units up front each month. You could use this information to access lower carrier fees and more perks.

4) Optimize each shipping cost in your supply chain

Another way to slash fulfillment costs is to estimate the fees you incur for shipping goods at every stage in your supply chain, then seek ways to reduce them.

To provide some inspiration, here are a few ways you can improve costs in your shipping processes:

Send raw materials to manufacturers in bulk.

Use cartonization to find the most economical packaging options.

Bundle bulk inventory for multiple SKUs into one shipment.

Price free shipping and returns into your product.

Give shoppers who order products in different warehouses the option to delay shipping to combine their items into a single package.

5) Position your stock and map transportation routes to reduce waste

When moving goods through your supply chain, wasted time, manpower, and fuel are just a few factors that can drive up fulfillment costs.

To ensure your products reach customers as efficiently and cost-effectively as possible, analyze your store’s customer data to understand the top geographical locations where your buyers reside.

Then, work with a reliable fulfillment house to distribute goods across warehouses in these critical locations to shorten inbound and outbound distances for transporting stock. You should also clearly lay out delivery routes. Use delivery routing software to map the best drop-off sequences for couriers to prevent inefficiency.

Routing and delivery software

6) Automate repetitive and time-consuming tasks

To slash fulfillment costs, incorporate automation into your logistical setup. Work with warehouses, fulfillment houses, or prep centers that understand the importance of implementing AI-backed solutions to streamline your logistics.

Look beyond your business niche for examples of how other successful brands restrain fulfillment costs and adapt their approaches to your store.

For instance, the U.S.-based electronics retailer Best Buy brought in 73 robots to aid sortation, synced its supply chain, and switched from regional distribution centers to metro eCommerce centers to upgrade its fulfillment speed and cost.

The result?

Best Buy can now pack up to 20,000 units per hour and has secured cost reductions for shipping bulky and heavy items.7) Provide omnichannel fulfillment options

Consumers’ busy lives mean they rarely have time to wait for packages to arrive.

Use this to your advantage by offering multiple shipping options. Not only will you avoid wasting time and money on getting goods to shoppers’ homes and multiple delivery attempts, but you’ll also boost customer satisfaction by providing convenient shipping services. Some cost-busting fulfillment options you can offer are:

Click and collect

Locker collections

Neighbor drop-offs

To get an idea of how powerful this switch can be, look no further than the big-box department store, Target. Target reduced fulfillment costs by packing orders at their retail locations and allowing in-store pickups. This strategic shift led to a 30% drop per customer order, and costs fell by almost 90% for same-day shipping options like curbside or in-store pickup. Additionally, Target fulfilled its “pay less” promise to customers by passing cost savings on to its customers.

See how Target lowered per order costs by 30%8) Use technology to gain a 360-degree view of your supply chain

One minute, your store is sufficiently stocked; the next, it’s running dangerously low on inventory with no restock units on the horizon.

Many eCommerce businesses experience this vicious cycle of fulfillment cost spikes and opportunity costs from lost sales. In October 2021 alone, shoppers saw two billion out-of-stock notifications due to limited supply chain visibility and inaccurate inventory predictions. The fix is a two-pronged approach to improve your supply chain.

Supply chain synchronization

Onboard an AI-backed supply chain management solution to link all components in your supply chain, from your manufacturers to your last-mile shipping carrier. This way, you’ll gain a clearer view of your store’s stock levels, inventory location, and fulfillment needs to control costs with ease.

Accurate inventory forecasting

Implement an AI-backed inventory forecast solution to take the guesswork out of managing stock levels.

While no inventory forecast is perfect, you can avoid costly human errors, which are often exacerbated by manual tools like spreadsheets and email chains.

The closer your eCommerce business comes to optimal stock levels, the fewer instances you’ll have to pay expensive rush orders and emergency stock distributions. This, in turn, will lower your eCommerce order processing costs.

Wrapping up — The blueprint for profitable eCommerce fulfillment

As a growth-focused eCommerce business, controlling fulfillment costs is essential for long-term success. But with high shipping rates, obscure fulfillment charges, and supply chain challenges to contend with, staying lean can be difficult.

But with the right strategy, partnerships, creativity, and mindset, you can overcome these and other hurdles to reduce your fulfillment costs and achieve bigger profits for your business.

And you can begin today. Start trimming down your fulfillment services, optimizing your shipping plans, upgrading shipping options, eliminating tasks through automation, and syncing your supply chain. Soon, you’ll have a low-cost fulfillment strategy that keeps your pockets full and your customers eagerly coming back for more.

About the Author

Rachel Go is the marketing director of MyFBAPrep, an international network of eCommerce 3PLs and prep warehouses with 50+ locations, 20M+ square feet of operating space, and the ability to reach any US customer in 1 to 2 days. MyFBAPrep handles item-level FBA prep and eCommerce fulfillment (pick/pack/ship) including Amazon FBM and Seller Fulfilled Prime. They also handle other marketplace fulfillment such as Walmart for enterprise merchants, at-scale forwarding and storage for Amazon aggregators, and B2B retail replenishment services including EDI.

MyFBAPrep provides access to strategic warehouse locations and a wide variety of eCommerce services with a single partnership, along with white glove customer service and best-in-class technology. Sellers can send items into a single MyFBAPrep location and let us handle shipment splitting, prepping, packaging, and shipping across their sales channels. We integrate with most major warehouse WMS platforms and client Order Management Systems offering real time inventory levels, order tracking and dashboard analytics across our network.