Simple Lot Tracking & Expirations Dates

Get yourself on the #1 inventory system for perishable goods. Works with Shopify!

Traceability Made Easy

Less spoilage, easy product recalls, efficient FIFO inventory

Less Spoilage

Know when every product will expire and quickly bring up any location holding expired products. Discard expired products for any number of reasons

Handle Product Recalls Easy

Identify product recalls and provide necessary FDA documents and statistics for each lot within your warehouse. Log any product lot movement

FIFO Inventory Method for Lots

Using first in first out on the visual warehouse layout will keep your inventory rotating through with oldest product picked first every time across multiple bin locations

What is Lot Tracking & Traceability?

When it comes to storage of perishable items, you'll need a way to identify when something expires so it can be removed from regular stock. Not only is this a requirement for any food supplier but it helps you maintain and cycle through an efficient inventory process. Here's what you need to know about lot tracking and expiration dates and how it's used.

Used In Manufacturing

When a manufacturer produces foods, the ingredients and batch date are assigned to the production run. That batch number is used to create a lot number for all inventory pertaining to the specific batch produced. This lot number is transferred with each transfer of inventory along the supply chain.

Used With These Products

Food & beverage

Drugs & medical supplies

Certain electronics

Vitamins & supplements

Chemicals

Cosmetics

Connected to Inventory

Whenever a new lot comes into the warehouse, the lot associated with that inventory, and the expiration date assigned to the lot are attached with that inventory and carried with the products to a bin location within the warehouse so it can be tracked around the warehouse.

Helps with Recalls

When the manufacturer of an item realizes their product has not met the standards of the FDA they will issue a recall. The recall will be sent out to anyone who has recently purchased the related affected lot numbers. If you have taken ownership of the lot affected, it is your responsibility to remove the lot from your current inventory. Having lot traceability in place will enable you to search for the lot and view all current locations within the warehouse storing this product so it can be removed.

Reduces Spoilage

Using lot tracking with expiration dates inside your WMS or inventory system helps reduce spoilage by better tracking which items need to leave the warehouse before expiring. Keeping spoilage at a minimum reduces your overall carrying cost of inventory.

Provides Records

With a lot tracking system in place, you'll be able to see exactly where that lot was moved about through the warehouse. Importantly the records necessary for FDA and other regulatory bodies are aligned closely with the lot traceability records produced by your lot tracking software. This saves time and helps keep operations organized.

How Does SKUSavvy Handle Lot Tracking?

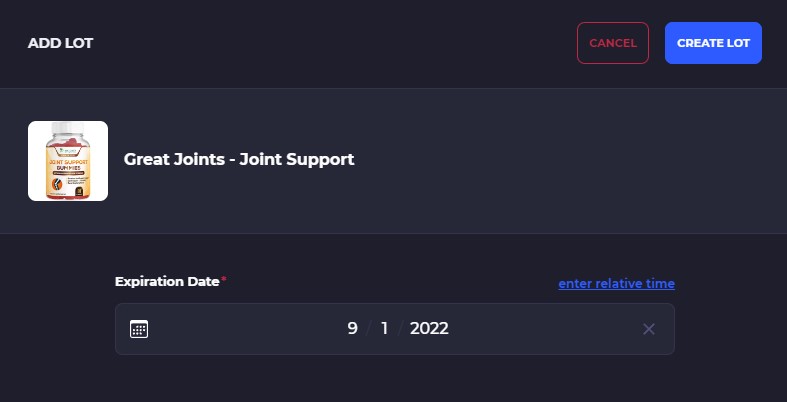

Lot Creation on Purchase & Check-In

During the purchasing and check-in process, perishable goods are assigned a lot number and expiration date which transfers to a bin location

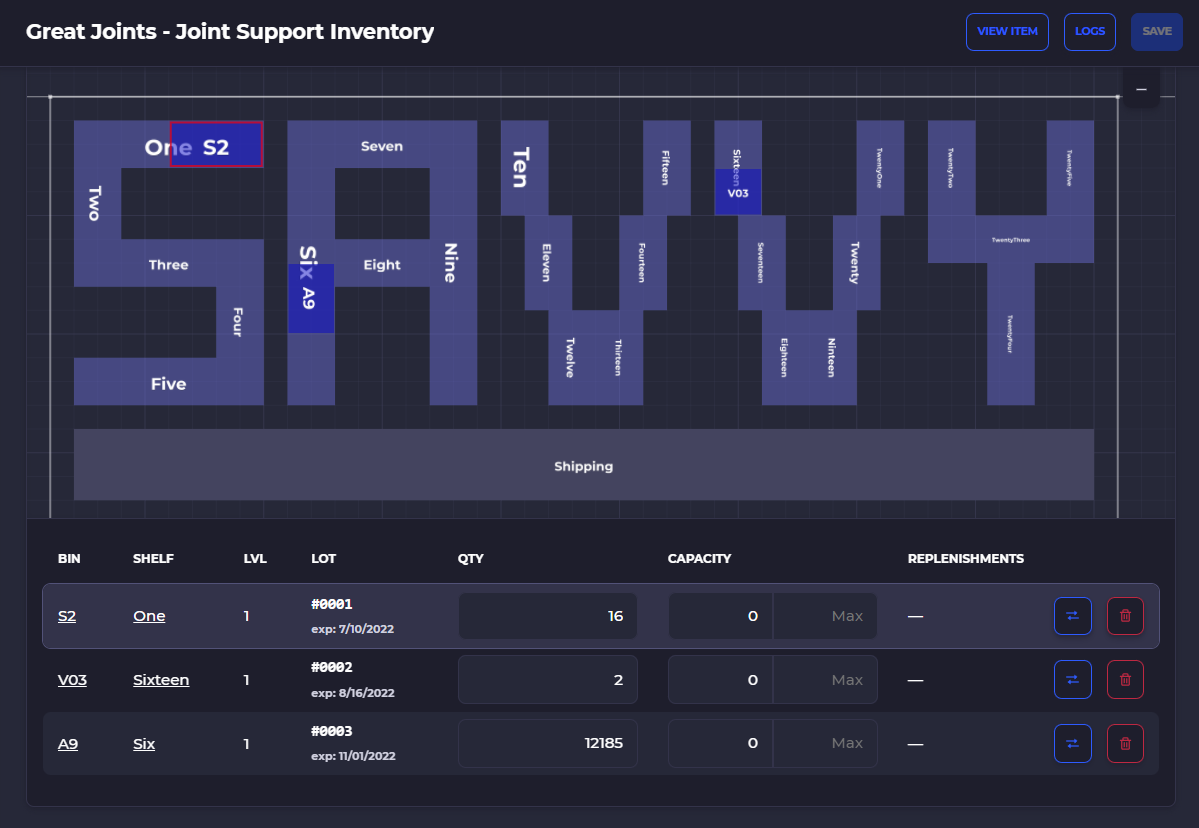

Bin Locations with Lot Tracking Built-In

Each bin location within holds information about lot numbers and ensures those lots are not stored within the same bin location ensuring proper traceability

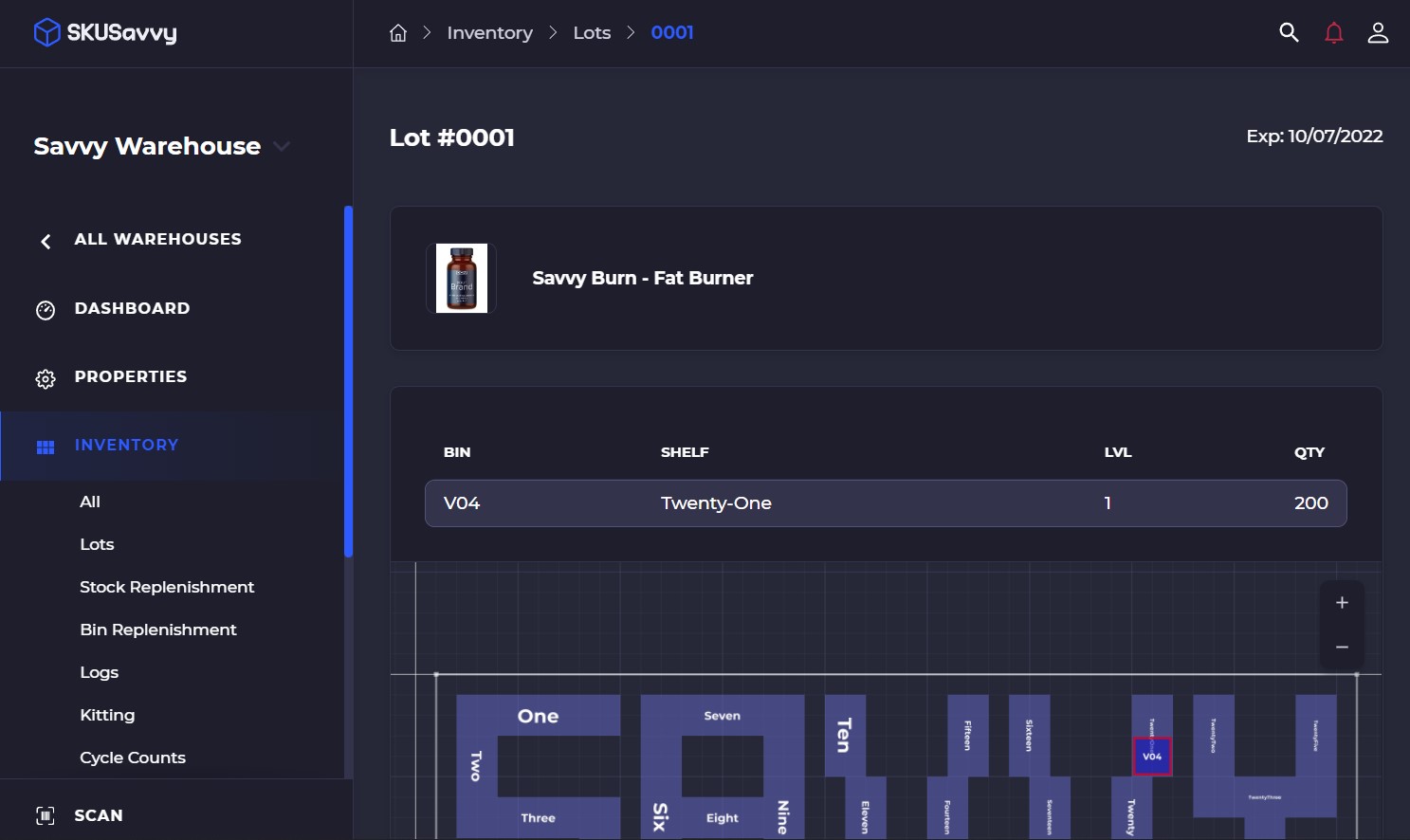

Visual Lot Tracking & Traceability Records

Handle product recalls quickly with visual identification of each lot and real-time product movement logs to identify and report on recall status across your inventory

Visual Lot Traceability

All You Need to Track Perishable Items

Your Inventory Source of Truth

Let SKUSavvy be a source of truth record for each lot coming into your warehouse

Visual Lot Traceability

View all lots for a specific product on your warehouse layout view for quick actions and easy recall

Enforced Lot Tracking Rules

Be sure no two lots for one product are confused within the warehouse with inbound lot routing

FIFO Picking

Keep your oldest product moving first with enforced picking that removes possibility for error

Expiration Date Alerts

Get notified of product that is expired within the warehouse and easily remove the product from stock

Single Bin Lot Control

Contain each lot to a different bin ensuring different lots are not confused during pick

Explore the SKUSavvy Stack

Run Your Warehouse

Everything you need to purchase inventory, move items around, track items and organize your warehouse

All Your Order Channels

Bring all your orders together in one place to easily make changes then pick, pack, and ship on time

Pick-Pack-Ship Faster

Fulfilling orders is made easier with automated batching and mobile shipping label printing from iOS or Android

Check Out These Cool SKUSavvy Features

3D Visual Warehouse Layout

Use 3D warehousing to find inventory faster and simplify put-away, picking, counting

Vendor PO Approval Portal

Fast and accurate vendor PO approvals with built-in portal to view or edit quantity & cost

Multi-Shopify Store

Connect multiple Shopify stores with SKUSavvy to enable global inventory and fulfillment